Years Of Experience

Aluminium Powder Coating Manufacturers in Chennai | 94444 09420

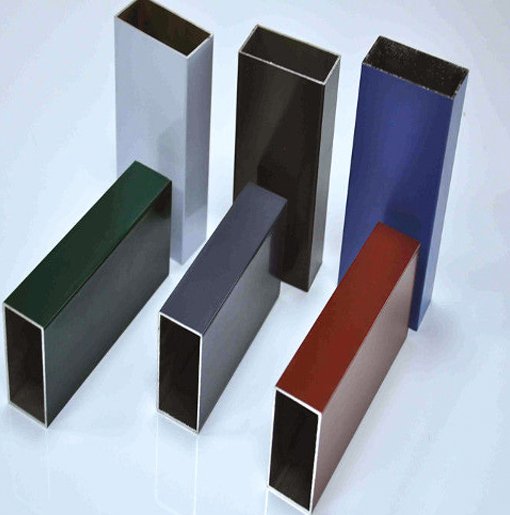

Aluminium powder coating involves the application of a fine powder comprising resin and pigment onto aluminium surfaces to achieve a robust and visually appealing finish. As leading aluminium powder coating manufacturers in India, Sri Lakshmi Industrial Coating employs cutting-edge technology and advanced techniques to deliver premium powder coated aluminium extrusions services for diverse applications.

Sri Lakshmi Industrial Coating extends its expertise in powder coating to enhance its product range for architectural and industrial purposes. Employing an innovative and eco-friendly powder coating technology, the company achieves an exceptional level of precision down to 1/1000 mm. This meticulous process encompasses powder dispersion, electrostatic charge application, and curing.

Customers benefit from the superior durability and long-lasting quality finish of aluminium through this process. The resulting coating is highly resistant to fading, scratching, wearing, and peeling, ensuring that the aluminium maintains its aesthetic appeal over time.

Our Aluminium Powder Coating Process

At Sri Lakshmi Industrial Coating, we’re dedicated to delivering top-notch powder coating solutions tailored specifically for aluminum items. Our meticulous process not only bolsters durability but also enhances the visual appeal of aluminum components, rendering them more resilient against corrosion, scratches, and fading. Here’s an overview of our aluminum powder coating procedure:

- Surface Preparation and Cleaning: We commence by meticulously degreasing and cleansing the aluminum surface to eliminate any traces of dirt, oil, or contaminants. This crucial step ensures that the surface is pristine, facilitating optimal adhesion of the powder coating and guaranteeing superior quality.

- Application of Powder Coating: Once the aluminum surface is impeccably prepped, we utilize an electrostatic spray gun to apply the powder coating. This method involves the precise deposition of charged powder particles onto the aluminum surface, enabling them to adhere uniformly via electrostatic attraction, resulting in a flawless coating.

- Curing Process: Following the application of the powder coating, we subject the aluminum components to a curing process in our specialized oven. This process enables the powder coating to melt and fuse seamlessly, creating a robust and long-lasting coating. Upon completion of the curing process, the components are allowed to cool.

- Stringent Quality Control: At Sri Lakshmi Industrial Coating, quality assurance is paramount. Prior to shipping, our dedicated team conducts rigorous quality checks to ensure that the powder-coated aluminum products meet our stringent standards. This meticulous scrutiny guarantees that our customers receive products of exceptional quality, every time.

Customization Options for Your Aluminium Powder Coating in Chennai

We understand that every project is unique, so we offer various customization options for your aluminium powder coating needs. Aluminium powder coating provides a seamless and attractive finish with powder coated aluminium extrusions that can withstand harsh environmental conditions, such as powder coated railings, and resist wear and tear. However, not all powder coatings are created equal, and customizing your aluminium powder coating can help you achieve the desired look and performance.

We Offer Quality Assurance and Sustainability to Our Clients

At Sri Lakshmi Industrial coating, the best aluminium powder manufacturers in India, we take pride in providing high-quality Powder Coated Aluminium Profiles that meet the highest quality and sustainability standards. We use environmentally friendly and safe materials, and our processes are designed to minimize waste and maximize efficiency. Additionally, we have a dedicated quality assurance team that ensures that every finished product meets our rigorous standards for quality and durability.